In recent years, secondary soil salinization has become a significant global environmental concern, stemming from both natural processes and human activities. It is now recognized as a major environmental risk. Currently, approximately 1 billion hectares of land worldwide are affected by varying degrees of salinization, representing about 10% of the total arable land globally. Furthermore, the affected area continues to expand annually by approximately 1.5–2.5 × 105 hectares (1). Projections indicate that by 2050, around 50% of the world's arable land will face adverse impacts from salinization. As a result, managing saline-alkali land is crucial to mitigate yield losses due to environmental stress and to achieve sustainable production with limited resources.

Efforts must be directed toward promoting the rational development and enhanced utilization of land, optimizing land management practices to improve overall agricultural productivity in saline-alkali areas, expanding effective cultivated land, and ensuring food production and security. Various strategies have been employed to address soil salinization's adverse effects on crop growth and soil properties, aiming to enhance soil quality and land productivity. For instance, studies have demonstrated that the application of organic soil amendments can effectively boost farmland productivity, especially in regions with poor-quality soils like saline-alkali soils.

One organic colloid used as a soil amendment is humic acid (HA), which has strong cation adsorption and exchange capabilities. HA can significantly improve soil structure, promote the formation of soil aggregates, increase soil organic matter content, reduce soil salinity and alkalinity, and stimulate crop growth, so it is considered an excellent soil amendment. The main component of another material, SOCO® SAT (SAT), is potassium polyacrylate. It is a SAP specially developed for use in saline-alkali soils that SOCO® took 1 year to develop. It is known for its superior water absorption in saline-alkali soils and contains Potassium ions are beneficial to the growth needs of crops. They are odorless, tasteless, non-toxic, and have good gelling properties. They are very suitable for use as a water retention improver for saline-alkali soil.

In addition, the salt-alkali tolerant polymers produced by SOCO® can effectively improve the physical and chemical properties of soil and. However, previous studies on such improvers have mostly focused on the physical and chemical properties of soil, and there have been few studies on their effects on water and salt transport in saline soils, especially the adaptability of soil improvers on saline soils and the response to the application of soil improvers.

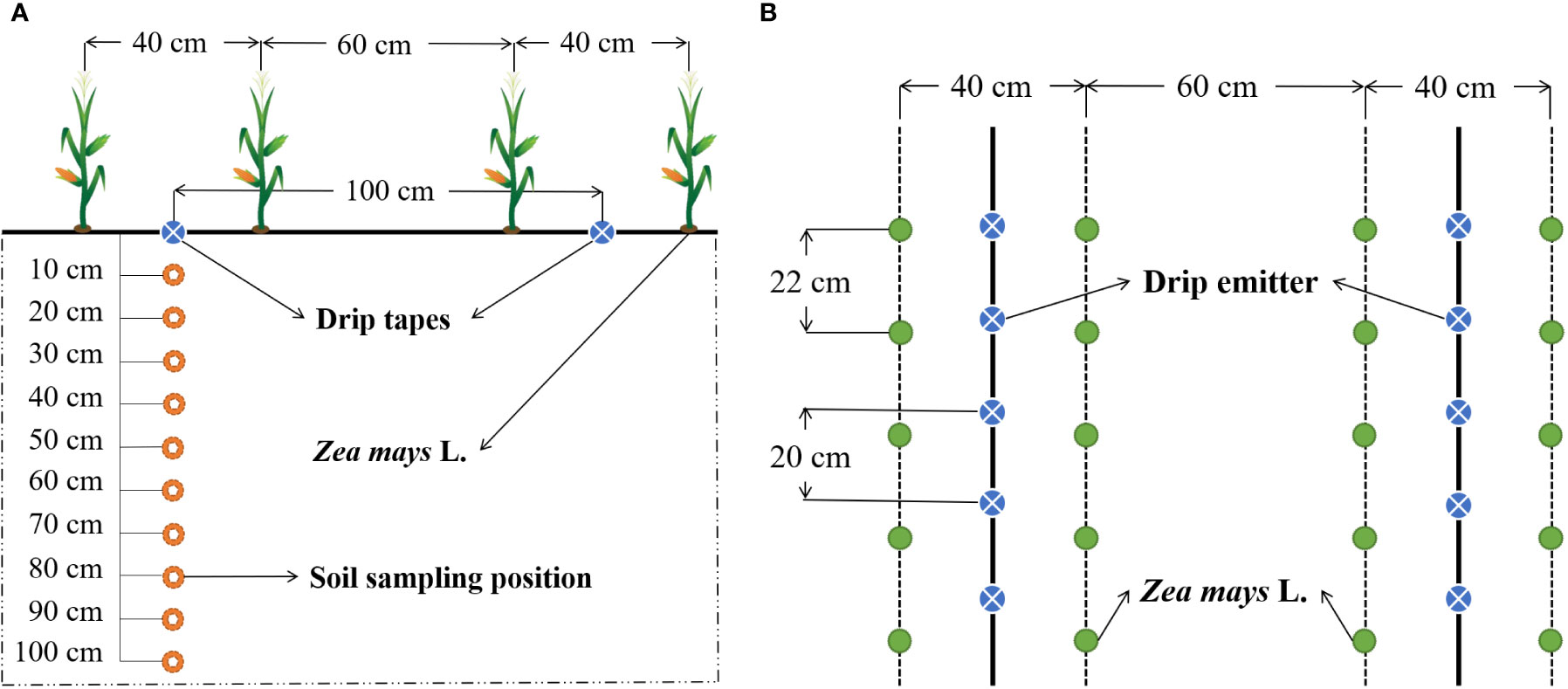

The effect of SOCO® polymer's salt-alkali resistant series products in practical applications. The seeds are sown in parallel rows, with wide (60 cm) and narrow (40 cm) row spacing, and a planting density of 22×50 cm (Figure 1). The plants are irrigated using a drip irrigation system that includes solenoid valves, pressure gauges, flow meters, screen filters, and fertilizer tanks. The drip irrigation tapes were laid along narrow rows with a spacing of 20 cm between emitters and a dripper flow rate of 1.27 L h-1. As treatments, the effects of the following four applications were evaluated:

(1) chemical fertilizer (CK);

(2) humic acid plus chemical fertilizer (HA);

(3) salt-alkali tolerant SOCO® SAT+chemical fertilizer (SAT);

amino acid fertilizer (AA) ). Each treatment was performed in triplicate for a total of 12 randomly arranged plots of 20 × 20m2.

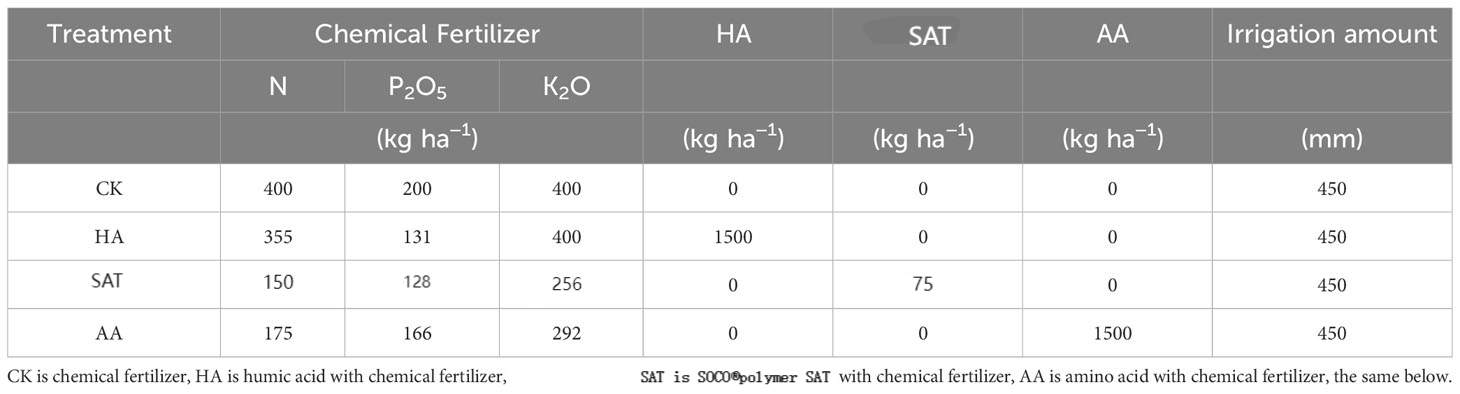

Each plot was fertilized with the same total amount of nutrients. Nitrogen, phosphorus and potassium were applied at 400 kg N ha-1, 200 kg P2O5 ha-1 and 400 kg K2O ha-1 respectively, of which 65% was used as base fertilizer and 35% as base fertilizer. top dressing. According to the established fertilizer requirements and irrigation quotas during the corn growth period, apply the water-soluble fertilizer (24-12-14) specially designed for corn drip irrigation into the field together with the irrigation water from the drip irrigation system. The distance for all treatments was 450 mm. HA black brown powder solid, pH 4.3, total nitrogen ≤ 3.0%, total phosphorus ≤ 1%, moisture ≤ 2.5%, spread at 1500 kg per hectare before sowing. SAT comes from SOCO®(white granular solid, pH 7~8, moisture ≤1.5%), and is spread at 75 kg per hectare before planting. AA yellow-brown powder solid, pH 3.5, total N≤15%, total P≤0.5%, total K≤3%, moisture ≤3.0%, spread per 1500kg. Hectares before planting. Rotary tillage is carried out immediately after spraying to a depth of 20-25 cm. According to the nutrient content of the soil amendment, the amount of fertilizer applied in the HA, SAT and AA treatment plots was adjusted to ensure the same amount of fertilizer was applied in each case, as shown in Table 2.

Table 2 Under the same conditions, the SAT series has the lowest cost.

SOCO® SAT series of Potassium Polyacrylate brings about a range of benefits when dealing with saline soils. Firstly, its accelerated absorption rates outperform traditional models, ensuring efficient water management whether the water is pure or saline. This series is specifically engineered to thrive in high-salt environments, showcasing superior performance in water absorption and retention. This enhanced hydration efficiency directly supports plant growth, even in challenging conditions with elevated salt levels. Furthermore, the SAT series' versatility extends to different water sources, making it a viable option in regions where higher salinity water is common. SOCO® SAT adaptability to various environments, be it pure or saltwater, establishes SAT as a reliable solution for soil management across diverse landscapes.

(1)Mustafa, G., Akhtar, M. S., Abdullah, R. (2019). Salt stress, microbes, and plant interactions: Causes and solution (Singapore: Springer), 1–19.